Unitsky String Technologies

|

Unitsky String Technologies |

|

Site news

|

11 April 2011 |

|

SDS Development Pilot Project: Preliminary conceptual study of high-rise buildings based on string technologies String Technologies Unitsky Pty Ltd presents the SDS Development Pilot Project: Preliminary conceptual study of high-rise buildings based on string technologies, interconnected with the "second level" rail city transport, and other sustainable developments based on string technologies (string bridges, runways and vacuum glass).

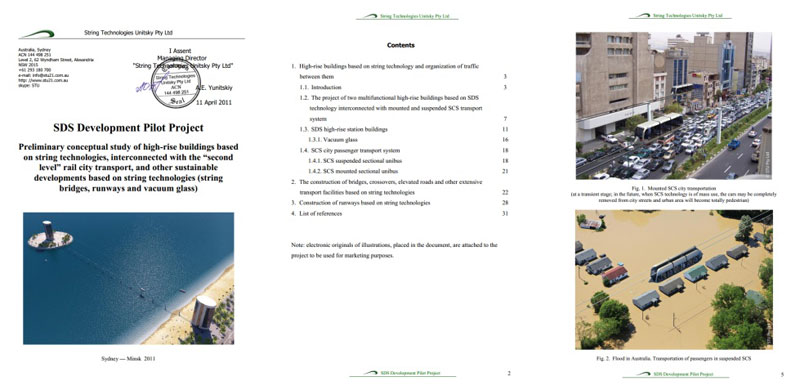

High-rise buildings based on string technology and organization of traffic between them The idea of transport system implementation for passenger traffic between two multifunctional station buildings based on SDS string technologies is briefly described in the Project by STU Pty Ltd. This is a demonstration project and its purpose is to show potential customers the advantages of string technologies in comparison with already existing city infrastructure. The Project offers a complex solution of the most acute problems for the cities and towns. The implementation of the most environmentally friendly and safe transport system, so called "SCS aerial metro" of the "second" and the "third" level, is represented in the Project. The possibilities of the system are not represented at a full volume in order to minimize investment costs without reducing investment attractiveness of the Project. The urgency of this Project results from existing and growing problems of the cities. The most acute problem is organization of speed, safe, economy-priced and environmentally friendly passenger and freight transportation in urban areas without considerable interference and, moreover, without destroying of existing natural landscapes, buildings and ecosystems. This article deals with the concept of high-rise station buildings, which is the basis of the development project. High-rise station buildings also serve as anchor supports for mounting pre-stressed strings of suspended (at a height of 50-100 m and more) and mounted (at a height of 5-10 m and more) SCS city transport of "the second level".

General view of two high-rise SDS station buildings, interconnected with mounted and suspended SCS SDS high-rise station buildings should be located at a distance of 500-1000 m. Approximately the same distance is between conventional transport stops. The distance between the buildings in this Project is 500 m. Passenger station of suspended SCS city transport is located at the top of a high-rise building. It is also the type of rail city transport. Suspended unibus, a special rolling stock, which consists of one to three and more sections is hanged to the bottom of two string-rails. The track structure between two adjacent buildings is implemented as a single span with no intermediate supports. Estimated deflection of a track structure under its own weight and the weight of a rolling stock in the midspan will be approximately 12-15 meters. Thus, a suspended unibus with passenger capacity of 25-75 persons and more may accelerate up to 60 km/h at a distance of 500 meters using for acceleration and deceleration its gravitational potential (rolling down and rolling up at an acceptable for city transport grade of 10-12%).

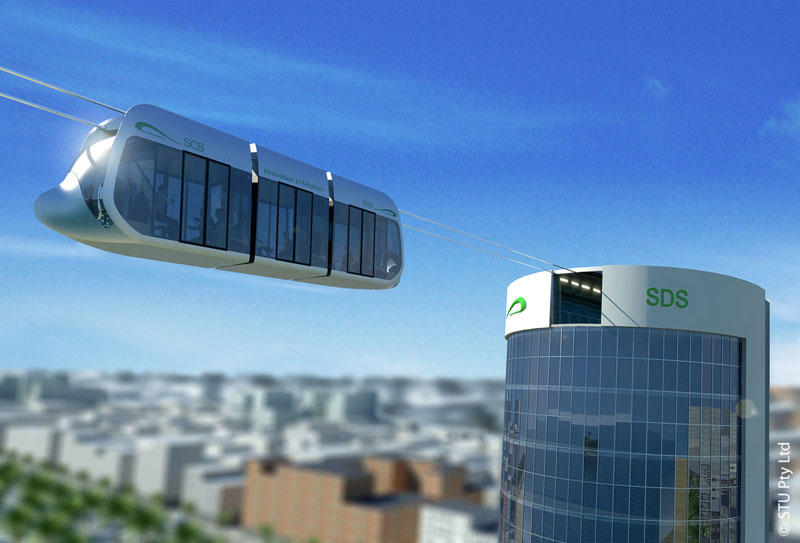

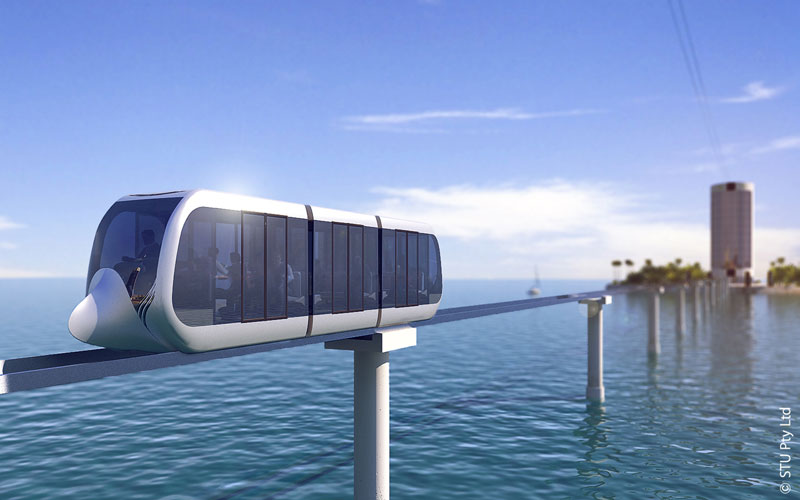

Suspended three-section unibus (passenger capacity of 75 persons) between station buildings Passenger station of mounted SCS city transport is located at the bottom of each high-rise building. Mounted SCS situated at a height of 5-10 m with the span length of 30-50 m is also the type of rail city transport. Mounted unibus, a special rolling stock, which consists of one to three sections and more with passenger capacity of 25-75 persons, is located on the top of two string rails.

Mounted three-section unibus (passenger capacity of 75 persons) between adjacent station buildings STU Pty Ltd provides innovative solutions for design and construction of high-rise buildings, civil and industrial constructions based on string technologies. High-rise string buildings and structures may be performed in the form of pre-stressed continuous vertical steel and concrete load-bearing frame (columns) clamped to anchor supports (at the bottom - to the foundation of the building, at the top - to the head mounted to the stiffening core, which might be, for example, the trunk of elevator shaft. Such pre-stressed string construction design, taking into account its strength and carrying capacity, will replace conventional steel, concrete and reinforced concrete load-bearing frames of high-rise buildings. It is proved by strength analyses, performed with the use of customary techniques in accordance with international standards. Reducing of material consumption and construction costs is achieved due to the fact that pre-stressed state of load-bearing frame is provided by high load-bearing strength, taking into account smaller transverse dimensions. Besides, vertical pre-stressed high strength reinforcement provides high stability of high-rise buildings during earthquakes and progressive collapse (when the building might be crushed like a house of cards under a single impact force). Reduction of terms and improving the quality of construction is ensured by the fact that monolithic floor structures may be concreted by cyclic lowering of formwork from the top downward along guide string-frame spatial lattice. At the same time all floor structures from the top to the bottom will be installed with the use of a single formwork without its removal. Exterior bearing walls of such buildings may be produced of string glass panes. The width of glass panes is 15-20 mm. The insulating properties of the units are the same as the insulating properties of a brick wall (the width of 1-1.5 m). As a result material consumption of the building will be reduced. Besides, the usable area of the building will be increased, due to the absence of conventional exterior walls. Decrease in building weight will provide decrease of foundation loads. As a result, its material consumption and cost will be reduced. It is a well-known fact that that the cost of a high-rise building foundation may account for 20-30% of the total construction costs.

Exterior bearing walls of the buildings are made of string vacuum glass panes Due to such decrease in labor costs (20-30% and more) and material consumption (20-30% and more), the string technology can be widely used in civil and industrial building construction. High strength of the frame provides the use of such buildings as anchor supports of Unitsky String Transport (UST) on "the second level" (mounted UST, track structure is located at a height of 5-10 meters and more), and on "the third level" (suspended UST, track structure is located at a height of 50-100 meters and more). UST stations and terminals may be arranged on any floor of the building, depending on the project. There is no need in strengthening of load-bearing frame of the string building. Besides, there is no rise in price. Accommodation facilities and office premises, shops, sports and entertainment centers, hotels and any environmentally friendly production departments may be located in multifunctional SDS high-rise station building.

Multifunctional SDS station building with apartments and office premises, The construction of bridges, crossovers, elevated roads and other extensive transport facilities based on string technologies STU Pty Ltd provides innovative solution for design and construction of road, rail and pedestrian bridges, crossovers, elevated roads and other extensive transport facilities (hereinafter referred to as the bridges). The bridges will meet the requirements of national standards. For example, in the Russian Federation such normative document is Construction Norms and Regulations 2.05.03-84 "Bridges and Pipes". It covers rail, road and pedestrian bridges, bridges for subway lines, light rail and the bridges for rail and road transport. Besides, string bridges meet the requirements of national standards for design of steel structures (in Russia it is Construction Norms and Regulations II-23-81 "Steel Structures"), European Norms (ENV) and new standards by USA for bridges (AASHTO). The regulations, taken into account in the design of string bridges, are not in contradiction. They complement each other, so these bridges can be built anywhere in the world, including Australia.

General views of a cable-stayed road bridge based on string technology String bridges are performed in the form of pre-stressed continuous constructions made of steel and reinforced concrete. The ends of the construction are mounted to anchor supports. The construction may be covered with road coverage, railroad tracks or covering for pedestrian bridges. Continuous pre-stressed string construction, clamped at the ends, due to its load-bearing capacity and the strength will be a substitute to conventional span bridges made of steel and reinforced concrete. It is proved by strength analysis carried out using conventional methods in accordance with applicable national and international standards. These analyses and calculations are planned to be carried out by the specialists of existing bridge design offices, experienced in design, construction and operation of flying and cable bridges, which construction is analogous to string bridges.

Cable-stayed road bridge based on string technologies Visually string bridges are similar to conventional bridges, as their know-how is in its construction. The construction of string bridges is light-weight and simple. At the same time there are no temperature welds along the whole bridge, regardless of its length. It provides increase in strength, stability and endurance of bridge coverage. The construction is less material-intensive, and as a result, construction cost is reduced. Besides, the loads on intermediate supports are significantly reduced. Anchor supports are as a rule located in the water. The requirements to the bearing capacity of soil are reduced, and, as a result, the construction of the whole bridge is simplified. The improvement of operation parameters will significantly reduce construction costs of string bridges in comparison with conventional bridges. It is proved by analyses and calculations implemented using conventional methods in accordance with applicable national and international standards.

View of the longitudinal string trusses, on which the roadway of a cable-stayed bridge is located If bearing construction of conventional bridges is implemented using string technologies (in the form of pre-stressed supporting string beams or string trusses), their cost is reduced by 2-3 times. At the same time their endurance and operation parameters are improved as the string bearing bridge structure along its entire length will be constructed uncut, without any cross gaps and seams. In particular, the coating of road bridges will be constructed without expansion joints. There is no need in the use of alternative materials and technologies and they may be constructed using conventional building equipment and construction machinery. For example, the cost of conventional road bridge across the river Volga is approx. USD 700 million. It is constructed by design office in the city of Twer. The central span of the bridge is 500 meters. At the same time a string bridge with two restaurants located on bridge pylons, interconnected with UST elevated track would cost approx. USD 350 million. Construction of runways based on string technologies STU Pty Ltd provides innovative solution for design and construction of airport runways. String runways will meet the requirements and standards of International Civil Aviation Organization (ICAO). Runway is supposed to be constructed in the form of pre-stressed monolithic slab with the clamped ends. The slab is made of reinforced concrete. Continuous pre-stressed string slab (width of 15-25 cm) made of reinforced concrete and clamped at the ends, due to its load-bearing capacity and the strength will be a substitute to conventional runways (width of 30-50 cm) made of reinforced concrete. It is proved by strength analysis carried out using conventional methods in accordance with applicable national and international standards. These analyses and calculations for specified objects are planned to be carried out by the specialists of existing design institutes, experienced in design of conventional runways (in Russia it is The State Design and Research Institute "Aeroproject"). The runways constructed based on string technologies have no expansion joints. It provides increase in strength, stability and endurance of runway coverage. The requirements to the bearing capacity of underlying gravel and sand foundation are reduced; the configuration of other airfield elements is simplified. Runway joints won't be destroyed, due to their absence. They will not give dynamic impact on the chassis and on the passengers inside of the cabin. When the plane is moving along conventional runway (see Fig. 17), the passengers, sitting in soft chairs, may count the number of expansion joints during each takeoff and each landing.

Runway based on string technologies If necessary, such slab made of reinforced concrete may be covered with a layer of asphalt without expansion joints and thermal cracking. The improvement of operation parameters will significantly reduce construction costs of string runways in comparison with conventional runways. It is known that a large aircraft may land on the solid ice of the lake. Though ice is a very weak material, and the water it lies on has no bearing capacity at all. But if the ice is cut into individual plates (small floes), then even a very light aircraft will not land on it. There is the same difference between string and conventional runways, due to the same performance of a slab on elastic foundation. It is proved by analyses and calculations carried out using conventional methods in accordance with applicable national and international standards. According to the Russian Federal State Unitary Enterprise "The Administration of Civil Airports (Airfields)", more than 100 runways are planned to be built in the Russian Federation in the nearest future. The cost per one runway varies from USD 40 million to USD 200 million. The use of string technology will provide reduction of costs by 20-30 per cent and even more. Besides, operation parameters of runways and their service life will be increased. |

|

© 1977—2017 Anatoly Yunitskiy. All Rights Reserved. |

||