Unitsky String Technologies

|

Unitsky String Technologies |

|

Site news

|

6 November 2015 |

|

EcoTechnoPark object: motor-in-wheel After mid of 2011 in EU countries, there were introduced requirements for energy efficiency indicators in electric engines in accordance with IEC 60034-30.2008. Analysis of world market requirements in prospect for 2011-2020 shows that in the future they will be introduced in other countries, as well. In addition, the use of electric engines with energy efficiency class lower IE2 will be limited, which corresponds to the existing at present class EFF1 under classifier CEMEP (European Committee of Manufacturers for Electrical Machines and Power Electronic - voluntary agreement between the European Committee of manufacturers for electrical machines and power electronics with the European Commission). Standard EU 60034-30 classifies electric engines efficiency factor in the following way:

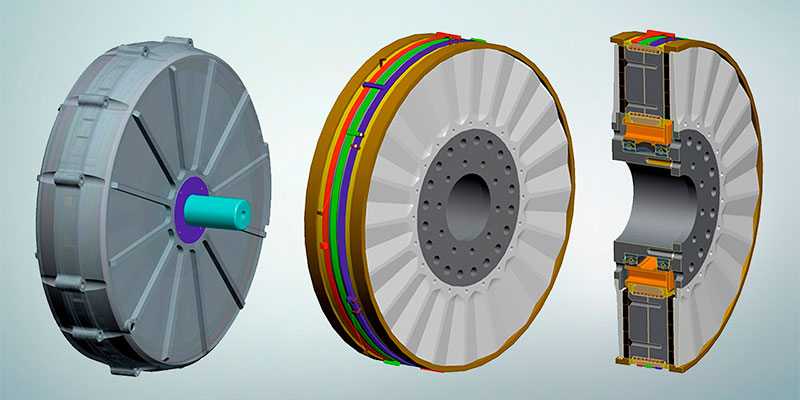

Reliability of motor-in-wheel (at design stage) is provided due to minimization of manual labour and the so-called "human factor". Small dimensions of motor-in-wheel will allow to significantly improve unibus energy efficiency, especially for high-speed unibus. In particular, allocation of brake and wheel-hub elements inside the electric engine allows to decrease the mid-section - cross sectional area.

Class IE5 belongs to the future class. Electric engines with such class are not in mass production yet. Introduction of new classes of energy efficiency for electric engines on the basis of international standard IEC 60034-30-1:2014 will push manufacturers to the development of electric engines of a new design with decreased losses and increased efficiency factor. Thus, development of motor-in-wheel and its integration into existing and newly created vehicles will result in expansion and use of renewable energy sources. At present, world industry does not produce motor-in-wheels for SkyWay having the required number of revolutions, horsepower, turning torque and weight and dimensional parameters. In addition, even serial motor-in-wheels of the required class are extremely expensive - their cost reaches 50 thousand USD/piece. In EcoTechnoPark, it is possible to organize manufacture of unique motor-in-wheels SkyWay both for own needs and for sale to a wide range of customers: from electric automobiles to wheelchairs and electric rickshas. The dimensions of electric engine mounted into the wheel are as follows: diameter from 150 to 350 mm, thickness from 15 to 100 mm, power - up to 150 kW, turning torque - up to 750 N×m, number of revolutions - up to 6,000 rpm. Application of the motor-in-wheel developed by SkyWay Group will already give economic benefits at a high-speed test track, which is planned for construction in EcoTechnoPark. Due to unique qualities of motor-in-wheel, the test section will be reduced up to 15 km (instead of planned 30 km), which will allow to achieve the pre-designed speed of 450 km/h at a shorter track and will cheapen the test section by approximately 50 mln USD. Moreover, the analysis carried out by the developer has shown that large-scale application of motor-in-wheel of SkyWay design in high-speed transportation will save billions of tons of fuel to the value of trillions of dollars in the future. |

|

© 1977—2017 Anatoly Yunitskiy. All Rights Reserved. |

||