Unitsky String Technologies

|

Unitsky String Technologies |

|

Site news

|

13 November 2015 |

|

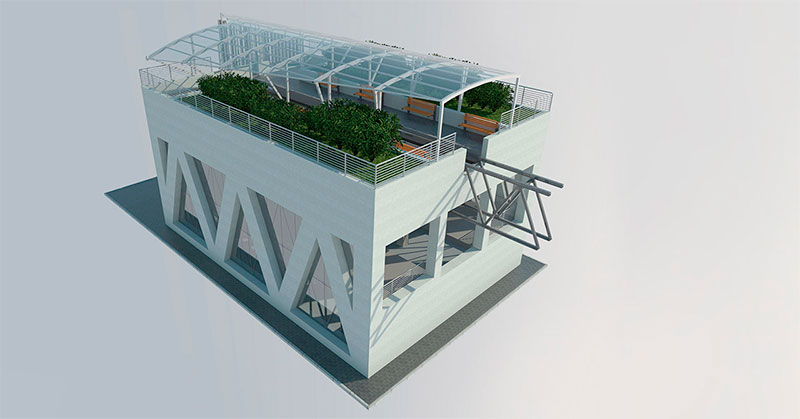

EcoTechnoPark object: terminal anchor support Anchor supports serve for fixing pre-stressed elements of string-rail overpass - reinforcement (prestressing strands and steel high-strength wires), rail head and body. High longitudinal forces in track structure, which anchor support shall bear, will also be created at ambient temperature change. For example, temperature change for one degree will lead to appearance of 24 kg force for each square centimeter of steel structure cross-section. Apart from that, the support will be subjected to longitudinal forces arising in the track structure at acceleration and braking of the rolling stock.

In total, horizontal forces affecting the terminal anchor support, resulting both from track structure prestressing and temperature and other impacts, with the possibility of once every 100 years (SkyWay overpass is designed in compliance with the requirements for permanent bridges and transport overpasses for service life of 100 years), can reach the values of 1,000 tons. This force applied at the height of about 10 m, will tend to overturn the support (overturn torque - approximately 10,000 t×m) and dislocate the support substructure in the ground (shear force - approximately 1,000 tons). Consequently, terminal anchor supports are rather complicated engineering structures designed and calculated for significant loads. Along with that, it is necessary to point out that standard intermediate anchor supports, which will be the majority in any targeted project (over 90% of all anchor supports), mounted every 3-5 km, will never experience the calculated load for the whole operation period (100 years). The fact is that forces from one and the other side of such anchor support will be equal and will balance each other. Therefore, intermediate anchor supports, in contrast to terminal supports, can be made less strong and more cost-effective, as they will carry out solely safety functions - in case of full breakage of the overpass from one side of such support, overpass destruction shall not spread on the "domino principle" to the overpass located on the other side of support. Absence of intermediate anchor supports on the territory of EcoTechnoPark is explained quite simply - all SkyWay tracks are short, with the length of about 1 km. However, such supports will appear beyond the land plot, when construction of remote high-speed track will start in 2016 (speed up to 500 km/h) with the length of 15 km. Anchor supports can be carried out in the form of metallic and reinforced concrete structures - both assembled and monolithic. Supports are made rigid and strong and they are mounted on special spatial substructures. Anchor supports can have double-purpose design - they can be combined with the load-bearing framework of different building structures and facilities - trade, entertaining, residential, industrial, etc. For example, these can be stations, terminals, depots, premises for processing equipment, turning sections of the track and other structures providing operability of transport and infrastructure complex SkyWay as a whole. Terminal anchor supports (as well as intermediate anchor supports) allow to carry out a string-rail overpass as pre-stressed, uncut (without construction and temperature joints), solid, light and openwork. It allows to reduce the cost of transport overpass by several times, and in specific cases - by many times. For example, a traditional bridge or overpass mainly carry their own weight - 90% and even 95% is own weight, and 5-10% is payload, i.e. the rolling stock. Therefore, traditional overpasses are like roads. String-rail overpasses are designed vice versa - the own weight of span structure makes less than 40% of total load, and the rolling stock - more than 60%. This fact has been proved at the test site of SkyWay first generation in town of Ozyory, Moscow region (2001-2009) - the track structure with the weight of 120 kg/m supported the payload having the weight of up to 15 tons (modified truck ZIL-131). It means that, for example, at the span of 36 m the weight of track structure (span structure) made only 4,320 kg (22% of total load), and the weight of rolling stock - 15,000 kg (78%). The most load-bearing elements of SkyWay string-rail overpass are specifically terminal anchor supports. Nevertheless, they are carried out as light, solid and cost-effective. As anchor supports SkyWay have no analogues in traditional transport overpasses, let us consider a usual (one of thousand) overpass support of high-speed railway, built by the Japanese in Taiwan about 10 years ago, as a prototype for comparison. Supports of this overpass experience such enormous loads that under each support in the ground, there are installed four bored piles with diameter of 2 m (!) and the length of up to 60 m (!). The mass of pile foundation alone for an ordinary support can reach 1,800 tons (for comparison: the mass of reinforced concrete foundation for terminal anchor support SkyWay does not exceed 500 tons). Therefore, an ordinary support of such a road, built under "advanced Japanese technologies", cannot cost less than 1 mln USD. In this case, it is necessary to pay attention to the fact that any SkyWay track will have only 2 pieces of terminal anchor supports, while at the track "Minsk - Moscow", for example, there would be 20,000 pieces of overpass supports, built under Japanese technologies (there are supports every 35 m). The advantages of anchor support can be seen at a specific example. Overpasses can be traditional, of a beam type, with temperature joints, and innovative - uncut, i.e. continuous, without joints. The latter, just due to uncut character of span structures, have twofold less material intensity and, consequently, twofold less cost of overpass. What benefit will it give when constructing a targeted project, for example, a high-speed transport overpass with the length of 700 km between Minsk and Moscow? The traditional overpass would cost at least 70 bln USD (that is 100 mln USD/km), SkyWay overpass, just due to its uncut character, - 35 bln USD, i.e. by 35 bln USD cheaper. For reference: This primary cost-cutting by 50 mln USD/km will be achieved due to anchor support, as it locks inside all longitudinal forces arising in an uncut track structure and decreases, other factors being equal, material intensity and overpass cost twofold. |

|

© 1977—2017 Anatoly Yunitskiy. All Rights Reserved. |

||