Unitsky String Technologies

|

Unitsky String Technologies |

|

Site news

|

8 January 2016 |

|

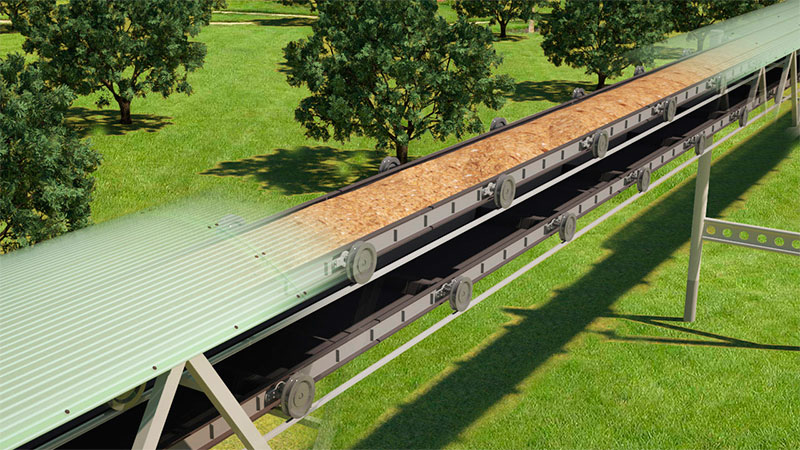

EcoTechnoPark object: cargo train-unicar for bulk cargo transportation A cargo train-unicar for bulk cargo transportation is a highly efficient comprehensive solution for implementation of continuous bulk cargo transportation for long (up to 1,000 km), average (100-200 km) and small (10-20 km) distances.

The operating motion speed is up to 40 km/h. Such a train is a variety of a product pipeline, as it operates on a non-stop basis due to having an indefinite length, being encircled and having an external drive. Transportation volume when using this type of special industrial conveyor on steel wheels makes from 1 to 250 million tons per year. The variant of a lightweight train-unicar, the one to be demonstrated in EcoTechnoPark, is designed for average transportation volumes up to 25 million tons per year. Area of system application:

A unicar looks like a belt-type conveyor consisting of a special belt with side walls, which are mounted on the axle with running wheels. The wheel rim, manufactured of steel, provides minimal rolling resistance when moving on a rail of the overpass string track. Advantages:

Due to the above facts, the transported bulk cargo, which has a design fractional composition, does not deteriorate in quality - that is, it is not additionally granulated, there are no dust fractions formed in it, it does not wear out the vehicle bunker, etc. Therefore, construction of a concentrating mill at the end of transport and logistics chain is not required (saving is 20-30 mln USD). Traditional conveyor systems are characterized by high values of energy consumption, which is explained by their design features (rolling resistance by "flexible rubber belt - steel roller of minor diameter" pair). This makes over 100 mln bending cycles per year with a radius of about 50 mm for each conveyor belt point. Using SkyWay rail-string conveyor technology will eliminate the specified deficiencies and will reduce energy consumption for cargo transfer by 6-9 times. For example, this transport system needs a drive of just 1.5-2 thousand kW capacity instead of drives with total capacity of 10-15 thousand kW. Apart from that, the conveyor belt durability is significantly increased - by 5-7 times compared to a conventional conveyor system due to a considerable decrease in the number of belt load cycles (by more than 1,000 times). Advantages of a train-unicar will make it possible for an operating company to save millions and dozens of million dollars as capital and operating expenses annually in each targeted project. For cargo transport complex operation, there will not be required power-drive stations of high capacity (like it is the case with conveyor systems and cargo cable ways). It will not be required to run electric power lines of high capacity, including along the whole transport system. In addition, it will not be necessary to replace high-priced conveyor belt every year. It will be easy to repair a reliable and long-life stationary external drive motor, operating on a normal mode all the time, in contrast to an electromotive and a diesel-powered locomotive on the railway, or a truck drive, which can fail to operate in an arbitrary place of the track. |

|

© 1977—2017 Anatoly Yunitskiy. All Rights Reserved. |

||