Unitsky String Technologies

|

Unitsky String Technologies |

|

Site news

|

23 May 2011 |

|

Complex research of high-speed intercity String Transport System String Technologies Unitsky Pty Ltd presents the complex research of high-speed intercity String Transport System including:

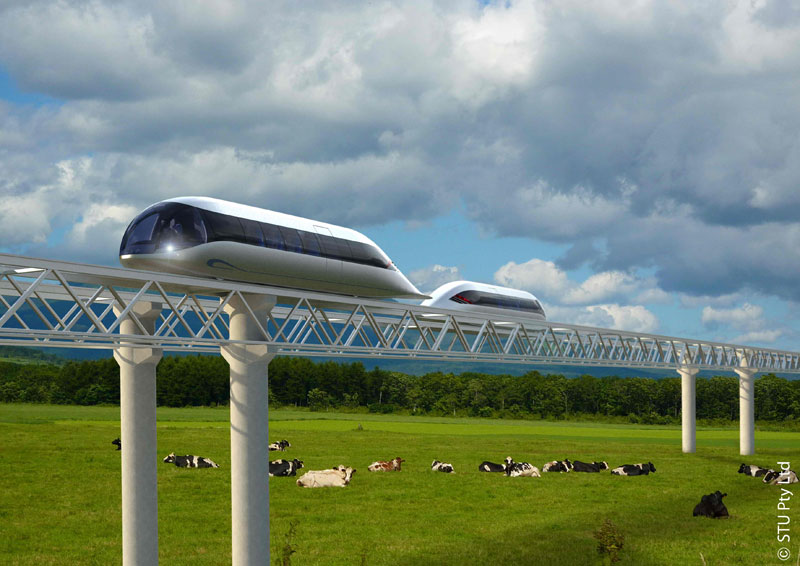

The basis for the complex research of high-speed intercity String Transport System is Statement of Work No.001, dated and effective 23rd of February 2011 submitted in connection with the Master Services Agreement by and between String Technologies Unitsky Pty Ltd (ACN 144 498 251) and Silk Rail Systems Limited (ACN 144 498 411), dated 17th of December 2010. Development purpose: Preliminary research of technical and economic parameters; development of the main technical solutions for the concept of a new high speed ground-level SRS transport system, based on UST technology; identification of the optimal criteria and parameters of the system. The Concept of High Speed SRS Transport System High speed SRS transport system is "the second level" transport system, which track structure is raised above the terrain and is mounted to the supports. It is a kind of suspended and cable-stayed bridges with a pre-stressed cable (string) wired to rigidity beam. It also serves as a railway for a rolling stock. Due to this peculiarity SRS railway has no expansion joints, which is the main problem of conventional railways. Depending on span construction SRS track structure may be designed in two forms. The first one is when the track structure is designed in the form of string-rail. The second one is when the track structure is designed in the form of string-truss.

String-rail track structure

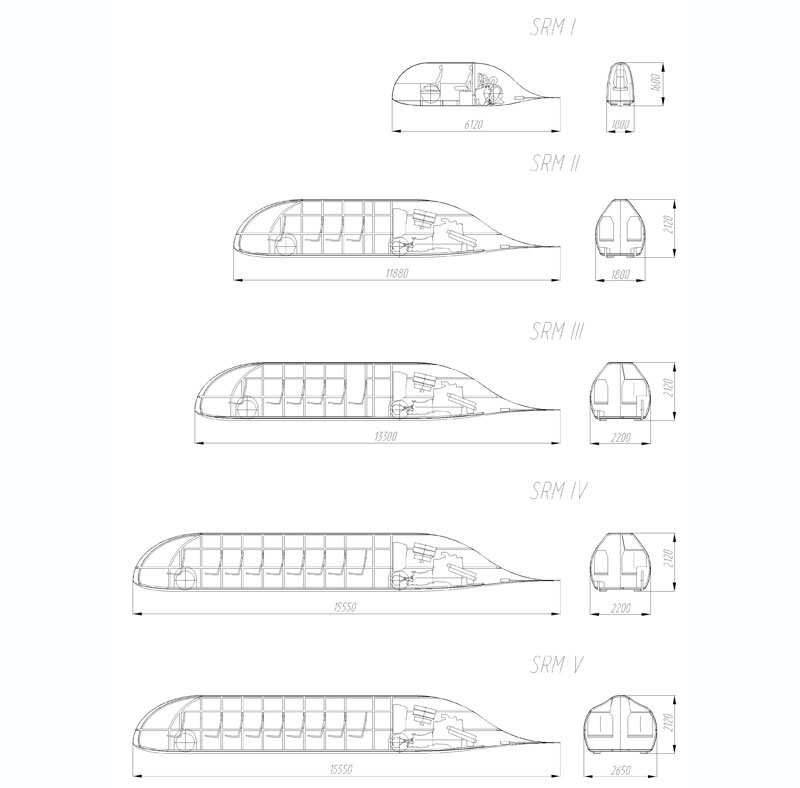

String-truss track structure The calculations of dynamic interaction of high speed rolling stock with string-truss track structure prove that it is much simpler to achieve a high ride of a train at a high speed when driving along string-truss track structure. However, this cheaper and more rigid span structure is less aesthetic than string-rail structure. Therefore, string-rail track structure is more preferable when the visual impact on the surrounding landscape should be reduced (for example, in the cities or when there is no need in high speeds). Material consumption of a track structure will be changed insignificantly, but the cost will be reduced significantly, due to lower string tension per each rail (required string tension in a string-rail is proportional to an estimated speed of a rolling stock). Rolling stock Rolling stock is a unibus. The unibuses may be divided into five categories depending on their passenger capacity. Each unibus category consists of several versions depending on its power supply:

The arrangement of both versions is the same. Front and middle parts of the body form a passengers compartment. Hind section is equipped with power unit.

Layout diagram of unibuses (Version1) The most efficient technical solutions such as, for example, the use of light metal alloys and high-strength plastic in body design, were implemented in the design of the whole high speed unibus:

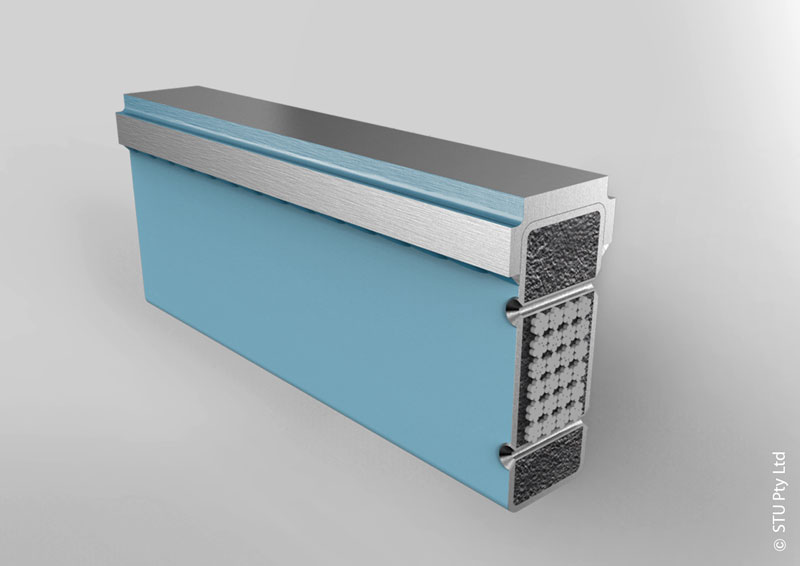

Track structure String-rail track structure consists of two string rails, which form a gauge. Track structure may also consist of two string-trusses. String-rails (string-trusses) are mounted to anchor supports. String-rails (string-trusses) lay on intermediate supports, which are installed between anchor supports. String-rail is uncut along the whole length steel beam of boxlike section, covered with rail top, reinforced with pre-stressed reinforced strings (stretched to 50-75% of tensile strength). The cables in a string are blocked with a special concrete, which increases their durability and corrosion resistance.

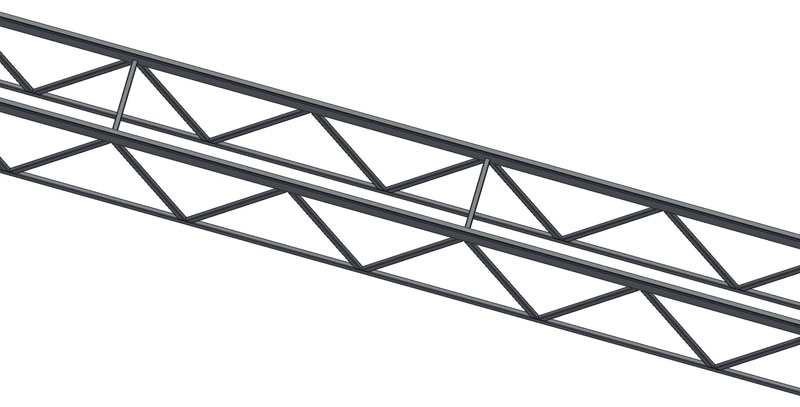

String-rail section String-truss is the part of a track structure which consists of two string-rails and two beams. They form upper rail track and lower power frame, interconnected with bridges and braces. String-beams of lower frame do not have rail top as compared to the upper rail track.

String-truss Infrastructure SRS transport system infrastructure consists of:

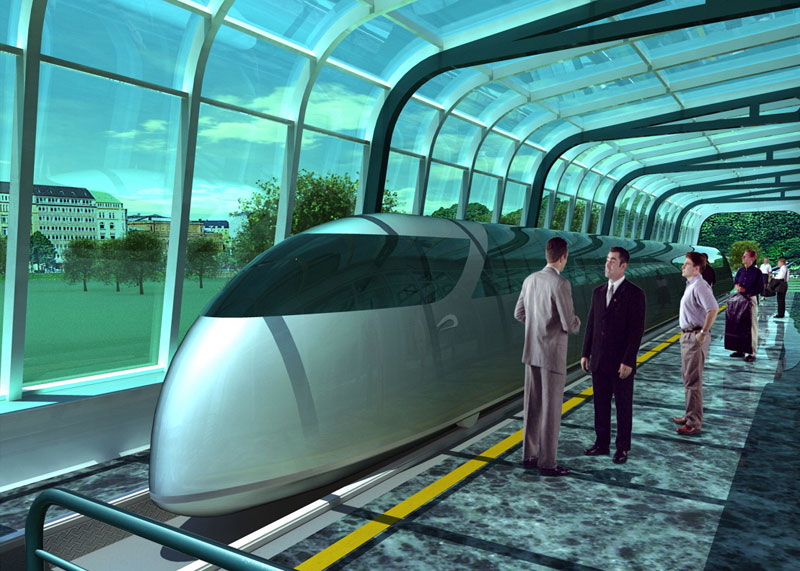

Platform of SRS passenger station

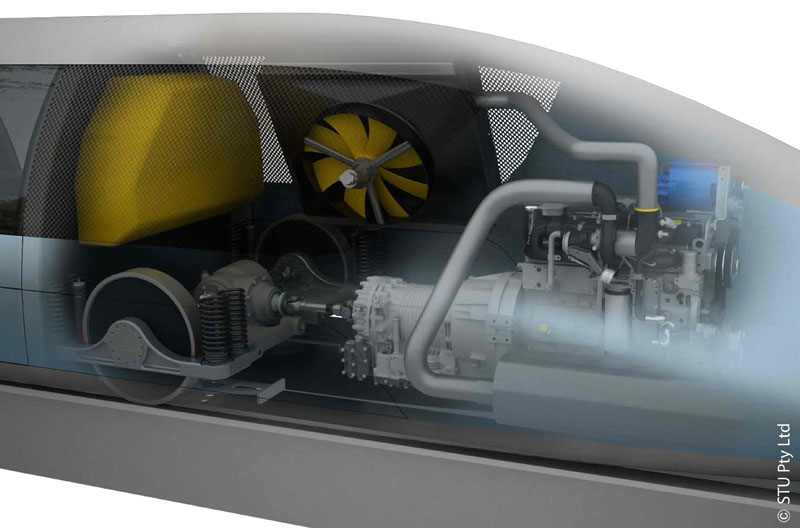

Transfer station General arrangement of high speed unibus major technical solutions Unibus is a four-wheel vehicle with streamlined aerodynamic body. Unibus is equipped with steel wheels. Its front and middle sections form a passenger compartment. Its power unit is located in the rear section. Power unit, power transmission and other units and devices that ensure unibus functioning are located in drive compartment.

General arrangement of unibus drive compartment for Version 1

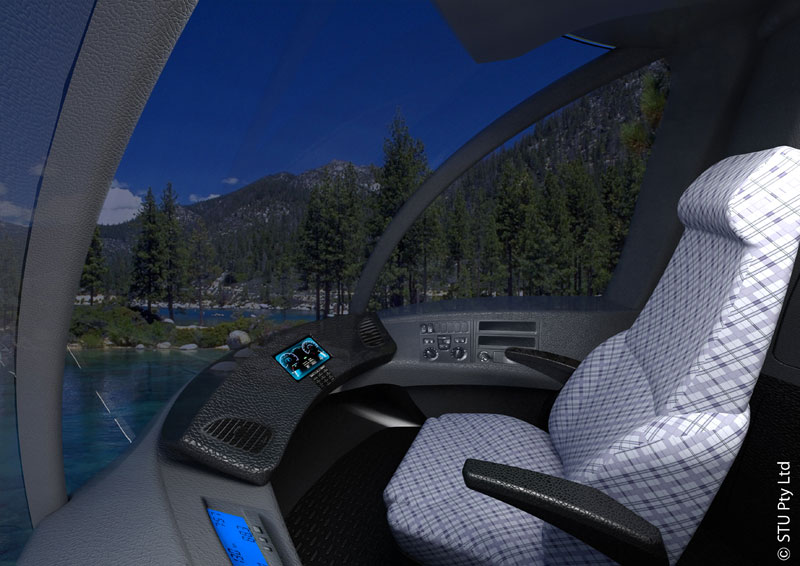

Passenger compartment of a high-speed unibus

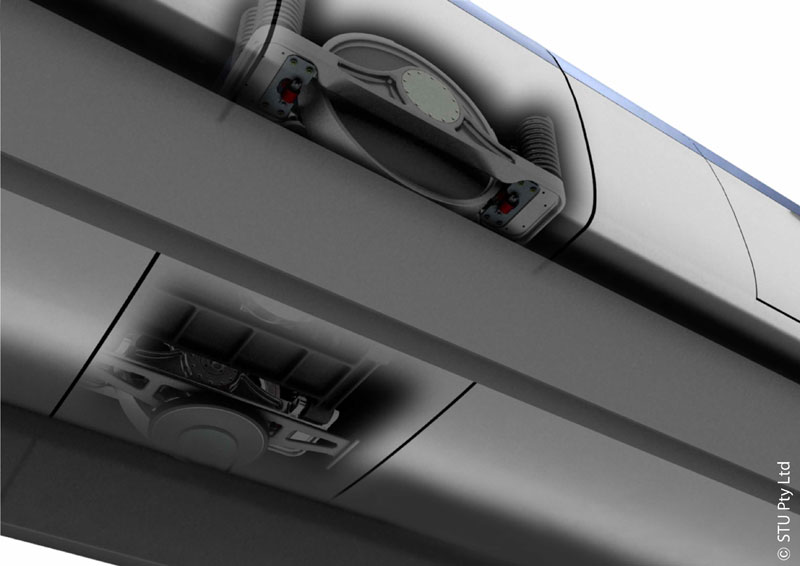

Operator's working place in a head unibus Four drive wheels serve as a guide anti-derailment device of a unibus (one device per each suspension block and bearing wheel). Guide wheels are in contact with lateral surface of string rail top. Guide wheels are pressed to a string-rail by initial effort. In the event of lateral exciting force unibus will be transversally displaced, until increasing resistance force to the lateral movement of guide wheels is equal to exciting transverse force. At the same time the contact of guide wheels, located on the other side of a unibus, with lateral runways of rail top is not lost. Upon termination of lateral exciting force guide wheels of a unibus take their original position, symmetric with respect to the left and right string-rails.

Guide anti-derailment device of a unibus All-weather operation and other advantages of high speed SRS intercity transport system High speed intercity SRS is a two-track transport system "of the second level". It is more compact and less material-intensive as compared to the existing transport systems "of the second level", such as monorail, train on magnetic suspension, railroad trestles. It results in decrease of capital expenses for its construction. Besides, the system has the following advantages:

High speed intercity SRS is resistant to flooding

High speed intercity SRS does not destroy flora and fauna Conclusions and recommendations A number of conclusions and recommendations might be drawn based on the results of "SRS High Speed Intercity String Transport System" Technical Analysis, aimed at determining the relevance and feasibility of new transport system implementation. Conclusions:

Recommendations:

|

|

© 1977—2017 Anatoly Yunitskiy. All Rights Reserved. |

||