Unitsky String Technologies

|

Unitsky String Technologies |

|

Site news

|

18 October 2015 |

|

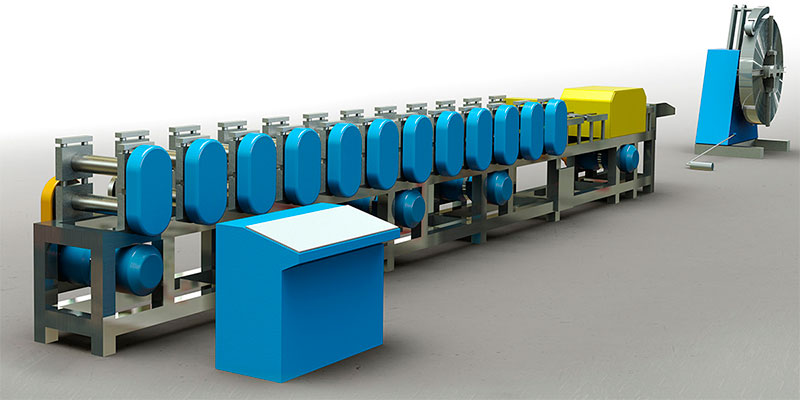

EcoTechnoPark object: portable rolling complex to manufacture special rail head The portable complex is designed to manufacture a unique seamless guiding rail profile for high-speed, urban and cargo transport, using special rolling equipment developed by SkyWay Group. At present, such a rail head is not released in industry, and re-equipment of existing rolling production for a new nomenclature would be rather expensive - several million dollars.

The profiling line consists of a metal uncoiler and a profiling machine. The profiling machine is a frame with processing rolling modules mounted on it. Dimensions: L × B × H = 15 × 1 × 2.2 m. This equipment allows to reduce overhead costs for manufacture of the required guiding profile made of high-strength strip steel, to simplify mounting on the track structure, decreasing the length of longitudinal and transverse weld seams by times. The portable rolling complex counts as innovative SkyWay processing equipment. It can be transported to the construction site of the targeted project, as it finds room in two automobile containers. Therefore, a rail head will be manufactured at the construction site and will be mounted on the overpass in the interval between one anchor support and the other (on average, 3 km) without a single weld seam, either longitudinal or transverse. Such a high-strength and pre-stressed rail head, being ideally smooth and continuous without any seams, will in fact provide a "velvet way" for at least a 50-year service life. If necessary, a rail head can be easily and quickly dismounted (for example, at the place of military operations, acts of terrorism or vandalism) and replaced for a new one. |

|

© 1977—2017 Anatoly Yunitskiy. All Rights Reserved. |

||