Unitsky String Technologies

|

Unitsky String Technologies |

|

Site news

|

30 October 2015 |

|

Comparison of SkyWay with suspension system Neyrpic Previously it was repeatedly indicated that the suspended monorails for transporting passengers and cargo are known in the world for a long time and Anatoly Yunitskiy is not a pioneer in this field. For example, the elevated transportation system in the city of Wuppertal was put into operation as far back as on March 1, 1901. There were many systems where wheels of the passenger cabins or a cargo truck rolled directly on a carrying rope.

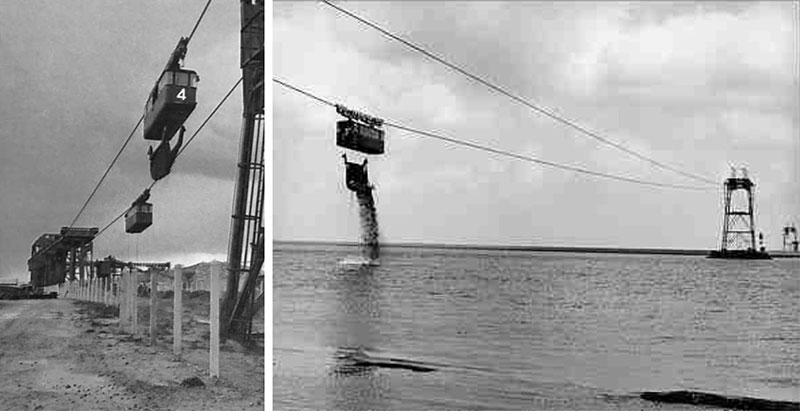

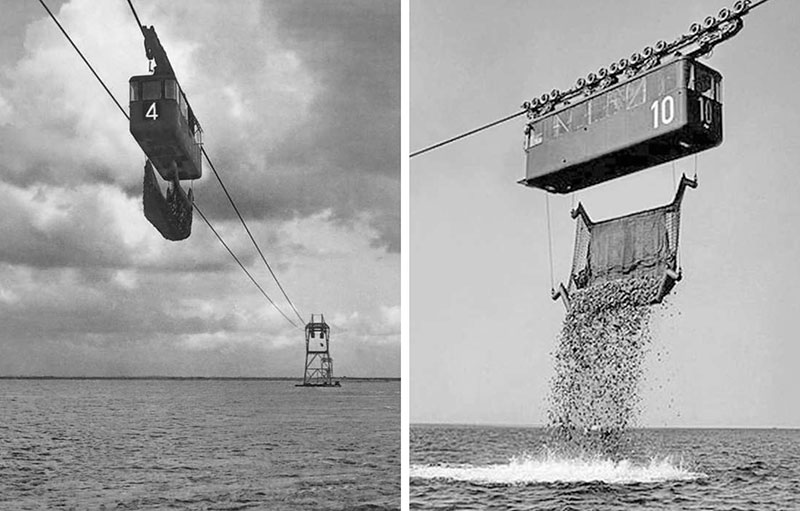

For example, the system of the company Neyrpic (France), which was established in the framework of the project "Delta" for the construction of the dam foundation "Grevelingendam" between the islands of Schouwen-Duiveland and Goeree-Overflakkee in 1963-1965.

However, for any competent technician and engineer at once obvious become the limitations of this vector of transport development, which has many disadvantages. In particular, due to the fact that the very foundation on which the wheel rolls, is a flexible and unsmooth (wavy) rope made up of many thin steel wires that have short service life, these disadvantages are:

Engineer Yunitskiy initially refused such a losing scheme of wheel rolling, as he understood all the drawbacks of this solution.

That is why the SkyWay rail transport of the elevated system has a high durability, high rigidity and evenness of the way, small energy consumption for movement, relative simplicity and low cost (without compromising quality), environmental friendliness, safety and ability to transport at speeds up to 500 km/h. |

|

© 1977—2017 Anatoly Yunitskiy. All Rights Reserved. |

||